In the realm of industrial automation, efficiency and precision reign supreme. Siemens’ WinCC Recipes emerges as a powerful tool, empowering users to streamline and optimize their manufacturing processes. Join us as we delve into the world of WinCC recipes, exploring their purpose, functionality, and best practices.

From creating and managing recipes to executing and monitoring them, this comprehensive guide will provide you with the knowledge and insights to harness the full potential of WinCC recipes. Discover how to enhance your automation systems, improve productivity, and ensure seamless operations.

WinCC Recipes Overview

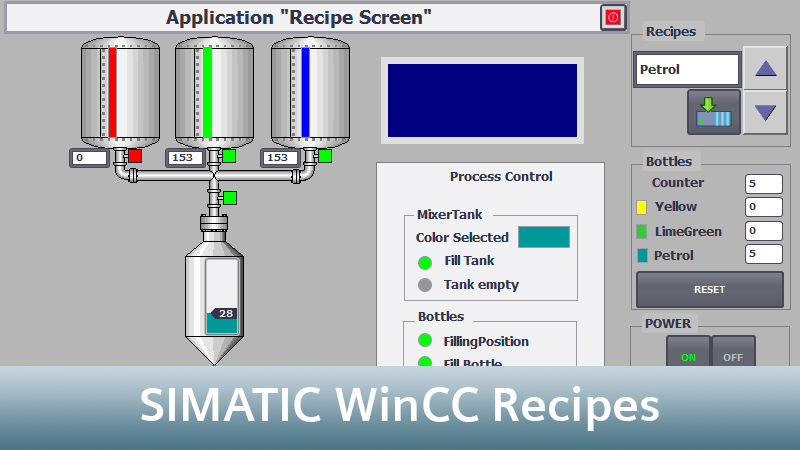

WinCC Recipes is a powerful tool that allows users to create and manage recipes for use in industrial automation systems. Recipes can contain a variety of information, such as ingredient lists, process parameters, and quality control checks. By using recipes, manufacturers can improve product quality, reduce production time, and minimize waste.WinCC

Recipes has been developed over many years, and it has evolved to meet the changing needs of manufacturers. The latest version of WinCC Recipes includes a number of new features and enhancements, such as support for multiple languages, improved security, and enhanced reporting capabilities.

Benefits of Using WinCC Recipes

There are many benefits to using WinCC Recipes, including:

- Improved product quality

- Reduced production time

- Minimized waste

- Increased efficiency

- Enhanced traceability

History and Evolution of WinCC Recipes

WinCC Recipes was first introduced in 2003. Since then, it has undergone a number of revisions and updates. The latest version of WinCC Recipes, version 7.0, was released in 2018.

Creating and Managing Recipes

WinCC Recipes provides a powerful toolset for creating, managing, and executing recipes in a variety of industrial automation applications.Creating a new recipe in WinCC is a straightforward process. First, you need to create a new project in WinCC and add a Recipe Server to the project.

Once the Recipe Server is created, you can start creating recipes. To create a new recipe, right-click on the Recipe Server in the Project Explorer and select “Add New Recipe”. This will open the Recipe Editor, where you can define the parameters and settings for your recipe.There

are two types of recipe parameters: process parameters and recipe parameters. Process parameters are the parameters that are used to control the process, such as temperature, pressure, and flow rate. Recipe parameters are the parameters that are used to define the recipe, such as the target value for a process parameter, the duration of a process step, or the order of process steps.Once

you have defined the parameters for your recipe, you can start to configure the recipe. This involves specifying the values for the recipe parameters, the order of the process steps, and the conditions that must be met before each process step can be executed.WinCC

Recipes also provides a number of tools for managing and organizing recipes. You can import and export recipes, create versions of recipes, and compare recipes. This makes it easy to keep track of your recipes and to make changes as needed.

Recipe Execution and Monitoring

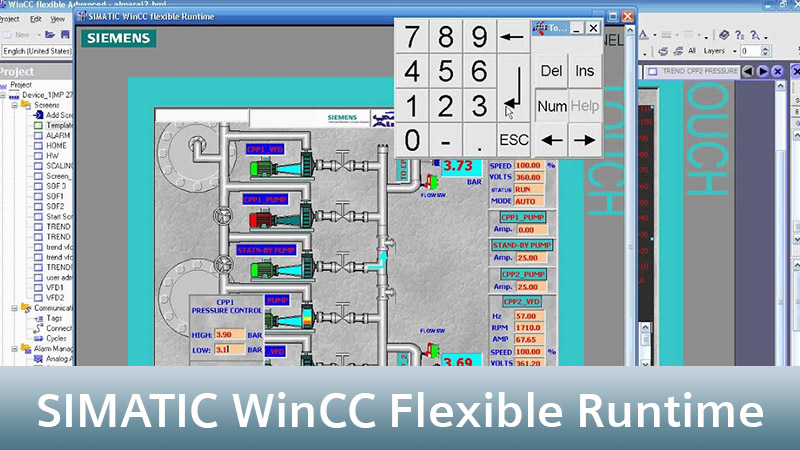

Executing a recipe in WinCC involves selecting the desired recipe from the Recipe Manager and initiating its execution. During execution, WinCC follows the recipe’s instructions, controlling process variables and monitoring the progress.

Monitoring Recipe Execution

To monitor recipe execution, WinCC provides real-time data on the current step, process values, and alarms. Operators can observe this data through the Recipe Execution window or HMI screens. Any deviations from the expected values or errors are promptly displayed, allowing for timely intervention.

Troubleshooting Recipe Execution Errors

In case of errors during recipe execution, WinCC generates alarms and notifications. These alerts provide detailed information about the error, including its cause and recommended corrective actions. By analyzing the error messages and taking appropriate measures, operators can quickly resolve issues and ensure smooth recipe execution.

Alarms and Notifications for Recipe Execution

WinCC allows for the configuration of alarms and notifications to provide real-time alerts during recipe execution. These alarms can be based on specific process values, deviations from expected values, or errors encountered. By receiving these notifications, operators can promptly respond to any issues and maintain optimal recipe execution.

Advanced Recipe Features

WinCC Recipes provides a range of advanced features that enhance the capabilities of recipe management and execution. These features include recipe sequencing and branching, recipe data logging and reporting, and recipe security and user management.

By leveraging these advanced features, users can create complex recipe sequences, monitor recipe execution, generate reports for analysis and documentation, and implement robust security measures to protect recipe data.

Recipe Sequencing and Branching

Recipe sequencing and branching allows users to define a sequence of steps or actions within a recipe. This feature enables the creation of complex recipes that can adapt to different conditions or user inputs during execution.

- Conditional branching: Allows recipes to branch to different steps based on specified conditions, such as process variables or user input.

- Looping: Enables the repetition of specific steps within a recipe a specified number of times or until a condition is met.

Best Practices for WinCC Recipes

WinCC Recipes offer a powerful tool for automating and managing complex production processes. To maximize their effectiveness, follow these best practices:

Design Considerations

- Define clear recipe objectives and scope.

- Use a hierarchical recipe structure to organize and manage recipes efficiently.

- Design recipes to be modular and reusable.

- Consider using version control to track recipe changes and ensure traceability.

Implementation Considerations

- Use a consistent naming convention for recipes and recipe elements.

- Use meaningful descriptions and comments to document recipe logic.

- Test recipes thoroughly before deploying them in production.

- Train operators on recipe operation and troubleshooting.

Maintenance Considerations

- Establish a regular schedule for recipe review and updates.

- Monitor recipe execution logs to identify potential issues.

- Implement change management procedures to ensure controlled recipe modifications.

- Provide documentation and training on recipe maintenance procedures.

Common Pitfalls and How to Avoid Them

- Avoid using complex or unnecessary logic in recipes.

- Use clear and concise language in recipe instructions.

- Test recipes thoroughly before deployment to minimize production downtime.

- Implement robust error handling mechanisms to prevent recipe failures.

Optimizing Recipe Performance and Efficiency

- Use efficient data structures and algorithms in recipe logic.

- Minimize the number of recipe steps and parameters.

- Optimize recipe execution by reducing unnecessary delays and dependencies.

- Monitor recipe execution performance and make adjustments as needed.

Last Word

Embracing WinCC recipes is a transformative step towards achieving automation excellence. By leveraging the advanced features and best practices Artikeld in this guide, you can unlock the full potential of your manufacturing processes. Embrace the power of WinCC recipes and witness a surge in efficiency, precision, and overall productivity.

FAQ Corner

What are the key benefits of using WinCC recipes?

WinCC recipes offer a plethora of benefits, including reduced setup times, improved product quality, increased production efficiency, and enhanced process consistency.

How do I create a new recipe in WinCC?

Creating a new recipe in WinCC involves defining recipe parameters, configuring values, and organizing them into a logical structure.

What are the different types of recipe parameters available?

WinCC recipes support a wide range of parameter types, including numeric, string, boolean, and date/time parameters.

How can I monitor recipe execution and troubleshoot errors?

WinCC provides real-time monitoring capabilities, allowing you to track recipe execution progress and identify any errors or deviations.

What are some best practices for designing and implementing WinCC recipes?

Best practices include defining clear recipe structures, using descriptive parameter names, and implementing version control to manage recipe changes.