Mitsubishi HMI recipes are a powerful tool that can help you streamline your manufacturing processes and improve efficiency. They allow you to store and reuse commonly used HMI settings, which can save you time and effort. In this guide, we will provide a comprehensive overview of Mitsubishi HMI recipes, including how to create, use, and troubleshoot them.

We will also provide examples of Mitsubishi HMI recipes for different applications.

Mitsubishi HMI recipes are a valuable asset for any manufacturer. By understanding how to use them effectively, you can improve your productivity and efficiency.

Mitsubishi HMI Recipes

Mitsubishi HMI recipes are pre-programmed sequences of operations that can be stored and recalled on Mitsubishi Human Machine Interfaces (HMIs). They allow users to automate complex tasks and processes, reducing the need for manual intervention and increasing efficiency.Recipes can be created for a wide range of applications, including machine control, data logging, and operator guidance.

They are particularly useful in industries such as manufacturing, automotive, and food and beverage, where repetitive tasks need to be performed with precision and accuracy.There are two main types of Mitsubishi HMI recipes:

- Standard recipes: These are pre-defined recipes that come with the HMI software. They can be used as-is or modified to suit specific needs.

- User-defined recipes: These are recipes that are created by the user. They can be tailored to specific applications and requirements.

Creating Mitsubishi HMI Recipes

Creating Mitsubishi HMI recipes is a straightforward process that can be completed in a few simple steps. By following these steps, you can create recipes that will help you to improve the efficiency and effectiveness of your HMI system.

Step 1: Create a New Recipe

To create a new recipe, open the Mitsubishi HMI software and select the “Recipe” menu. Then, click on the “New” button. This will open a new recipe window.

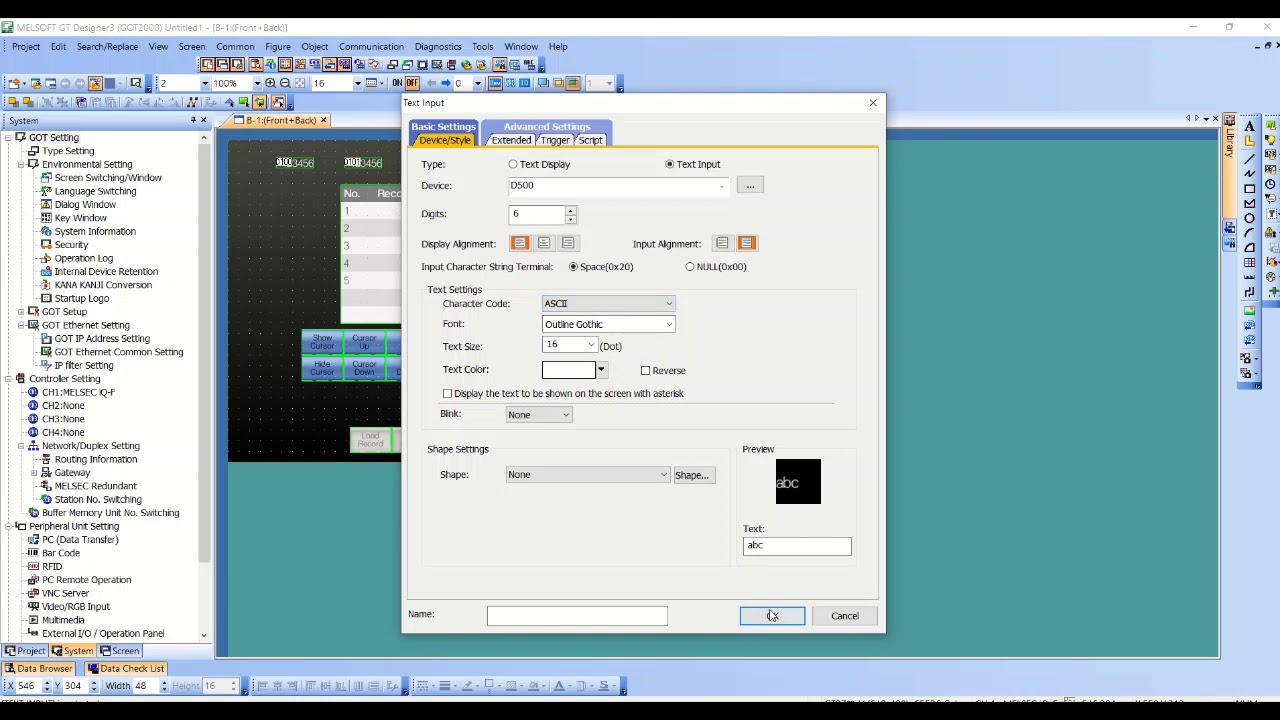

Step 2: Configure the Recipe Settings

The first step in creating a recipe is to configure the recipe settings. These settings include the recipe name, the recipe description, and the recipe type. The recipe name is the name that will be displayed in the HMI software.

The recipe description is a brief description of the recipe. The recipe type is the type of recipe that you are creating.

Step 3: Add Ingredients to the Recipe

Once you have configured the recipe settings, you can add ingredients to the recipe. To add an ingredient, click on the “Add Ingredient” button. This will open a new ingredient window.

Step 4: Configure the Ingredient Settings

The next step is to configure the ingredient settings. These settings include the ingredient name, the ingredient description, and the ingredient quantity. The ingredient name is the name of the ingredient. The ingredient description is a brief description of the ingredient.

The ingredient quantity is the quantity of the ingredient that you want to add to the recipe.

Step 5: Save the Recipe

Once you have added all of the ingredients to the recipe, you can save the recipe. To save the recipe, click on the “Save” button. This will save the recipe to the HMI software.

Best Practices for Creating Mitsubishi HMI Recipes

There are a few best practices that you can follow when creating Mitsubishi HMI recipes. These best practices include:* Use a descriptive recipe name. The recipe name should be descriptive enough so that you can easily identify the recipe later.

- Use a brief recipe description. The recipe description should be brief enough so that you can quickly understand the purpose of the recipe.

- Use a specific recipe type. The recipe type should be specific enough so that you can easily find the recipe later.

- Use a consistent ingredient naming convention. The ingredient naming convention should be consistent so that you can easily identify the ingredients later.

- Use a consistent ingredient description convention. The ingredient description convention should be consistent so that you can easily understand the purpose of the ingredients later.

- Use a consistent ingredient quantity convention. The ingredient quantity convention should be consistent so that you can easily measure the ingredients later.

By following these best practices, you can create Mitsubishi HMI recipes that are efficient, effective, and easy to use.

Using Mitsubishi HMI Recipes

Mitsubishi HMI recipes provide a convenient and efficient way to manage and execute complex processes on Mitsubishi HMIs. They can be used in a variety of applications, including:

Manufacturing

Recipes can be used to control production processes, ensuring consistent quality and efficiency.

Food and beverage

Recipes can be used to create and manage recipes for food and beverage products, ensuring accurate and consistent results.

Healthcare

Recipes can be used to manage patient data, medications, and treatments, ensuring patient safety and accuracy.Recipes can be loaded and executed in a variety of ways, including:

Manually

Recipes can be loaded and executed manually using the HMI’s built-in recipe manager.

Automatically

Recipes can be loaded and executed automatically using a PLC or other automation device.

Remotely

Recipes can be loaded and executed remotely using a PC or other remote device.Mitsubishi HMI recipes can be used to solve a variety of common problems, including:

Inconsistent production quality

Recipes can help to ensure consistent production quality by providing a standardized set of instructions for operators to follow.

Errors in data entry

Recipes can help to reduce errors in data entry by providing pre-defined values for operators to select from.

Lost or damaged data

Recipes can help to protect data from being lost or damaged by providing a backup copy of the recipe data.

Loading Recipes

Recipes can be loaded into the HMI using a variety of methods, including:

USB flash drive

Recipes can be loaded into the HMI from a USB flash drive.

Ethernet

Recipes can be loaded into the HMI over an Ethernet network.

Serial port

Recipes can be loaded into the HMI using a serial port.

Executing Recipes

Once a recipe has been loaded into the HMI, it can be executed using a variety of methods, including:

Manually

Recipes can be executed manually using the HMI’s built-in recipe manager.

Automatically

Recipes can be executed automatically using a PLC or other automation device.

Remotely

Recipes can be executed remotely using a PC or other remote device.

Troubleshooting Mitsubishi HMI Recipes

Mitsubishi HMI recipes are a powerful tool for automating HMI tasks, but they can sometimes be tricky to troubleshoot. Here are some common errors that can occur when using Mitsubishi HMI recipes, along with some solutions:

Error: Recipe not running

- Make sure that the recipe is enabled.

- Check that the recipe is assigned to the correct HMI screen.

- Verify that the recipe is not paused or stopped.

Error: Recipe not completing

- Check that the recipe is not waiting for an input from the operator.

- Verify that the recipe is not encountering any errors.

- Make sure that the recipe is not configured to loop indefinitely.

Error: Recipe not producing the desired results

- Check that the recipe is configured correctly.

- Verify that the HMI is receiving the correct data from the PLC.

- Make sure that the HMI is displaying the correct data.

Advanced troubleshooting techniques

If you are still having trouble troubleshooting your Mitsubishi HMI recipe, you can try the following advanced techniques:

- Use the HMI’s debug mode to trace the execution of the recipe.

- Contact Mitsubishi technical support for assistance.

Example Mitsubishi HMI Recipes

Mitsubishi HMI recipes offer pre-configured settings for various applications, enhancing the efficiency and functionality of HMI systems.

Temperature Control Recipe

This recipe configures the HMI to monitor and control temperature parameters within a specific range. It includes settings for temperature sensors, control loops, and alarm triggers. The recipe ensures accurate temperature regulation, preventing equipment damage or product spoilage.

Motion Control Recipe

Designed for applications involving motion control, this recipe provides settings for motor drives, encoder feedback, and motion profiles. It enables precise positioning, speed control, and synchronization of multiple axes, improving machine efficiency and product quality.

Data Logging Recipe

This recipe configures the HMI to collect and store data from various sources, such as sensors, controllers, and external devices. It allows for historical data analysis, performance monitoring, and troubleshooting. The data logging capability provides valuable insights into process trends and helps identify areas for optimization.

Recipe Management Recipe

This recipe provides a framework for managing and transferring recipes between different HMI devices. It simplifies the sharing of recipes across multiple machines, ensuring consistent settings and process parameters. The recipe management capability reduces setup time and improves production efficiency.

Communication Recipe

This recipe configures the HMI for communication with external devices, such as PLCs, controllers, and databases. It supports various communication protocols, enabling data exchange, remote monitoring, and system integration. The communication recipe facilitates seamless communication and data exchange, enhancing the overall system functionality.

Last Recap

We hope this guide has provided you with a comprehensive overview of Mitsubishi HMI recipes. If you have any further questions, please do not hesitate to contact us. We are always happy to help.

Helpful Answers

What are the benefits of using Mitsubishi HMI recipes?

There are many benefits to using Mitsubishi HMI recipes, including:

- Reduced setup time

- Improved accuracy

- Increased efficiency

- Reduced errors

How do I create a Mitsubishi HMI recipe?

To create a Mitsubishi HMI recipe, follow these steps:

- Open the HMI project in GX Works3.

- Click on the “Recipe” tab.

- Click on the “New” button.

- Enter a name for the recipe.

- Select the settings that you want to include in the recipe.

- Click on the “OK” button.

How do I use a Mitsubishi HMI recipe?

To use a Mitsubishi HMI recipe, follow these steps: